Optimizing Efficiency Through Retrofitting: When and Why It's Essential

In the dynamic world of printing and converting, staying ahead of the curve is crucial. Upgrading your machinery through retrofitting can significantly enhance performance, extend the lifespan of your equipment, and reduce operational costs. Here’s a comprehensive guide on when and why to retrofit your equipment, organized into clear, actionable points.

When to Retrofit

1. PCs & Hardware

*Lifecycle: 3-5 Years

•Indicators for Change:

π Performance degradation

π Obsolescence

π Technological advancements

*Suggested Actions:

Year 3: Begin performance evaluation.

Year 4: Allocate budget and source new PCs and hardware.

Year 5: Implement hardware upgrades.

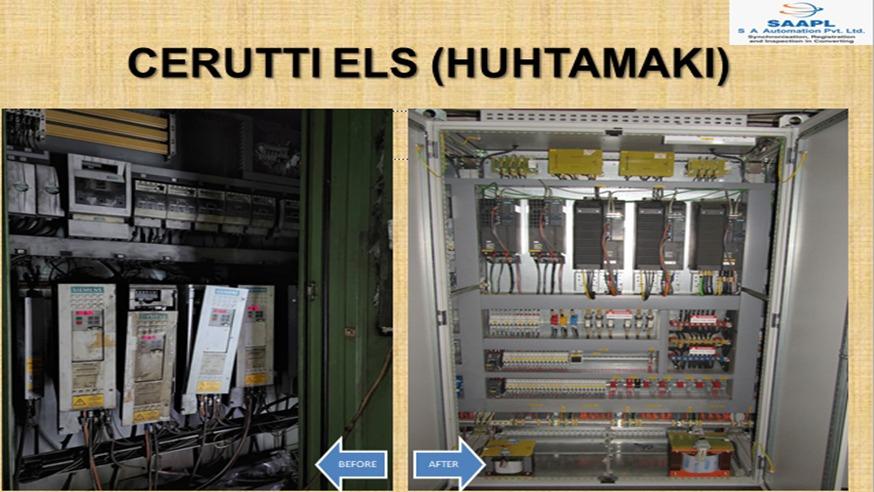

2. Drives & Control System

*Lifecycle: 5-10 Years

•Indicators for Change:

π Reliability issues

π Performance gaps

π Technological innovations

π End of life (EOL)

*Suggested Actions:

Year 5: Conduct a thorough assessment.

Year 6-7: Plan for phased upgrades.

Year 8-10: Implement upgrades to ensure enhanced performance and reliability.

3. Mechanical Components

*Lifecycle: 10-15 Years

•Indicators for Change:

π Wear and tear

π Rising maintenance costs

π Technological upgrades

π Changing production requirements

*Suggested Actions:

Year 10: Begin comprehensive inspections.

Year 11-12: Plan for gradual replacement of key mechanical parts.

Year 13-15: Complete replacement or major overhaul.

4. Performance Monitoring and Analysis

•Indicators for Change:

π Efficiency

π Output quality

π Operational costs

*Suggested Actions: Regular assessments and tracking KPIs.

5. Maintenance and Repair Records

*Indicators for Change:

π Frequent breakdowns

π Recurring issues

π Rising repair costs

*Suggested Actions: Review logs and analyze repair trends.

6. Technological Advancements

*Indicators for Change:

π Availability of new technologies

π Compatibility with existing systems

*Suggested Actions: Stay updated and assess integration potential.

7. Operational Demands

*Indicators for Change:

π Increased production needs

π Higher quality standards

*Suggested Actions: Evaluate machinery capabilities and plan for upgrades.

8. Regulatory Compliance and Safety

*Indicators for Change:

π Changes in regulations

π Updated safety standards

*Suggested Actions: Ensure compliance and upgrade safety features.

Why Retrofit?

1) Cost-Effective Modernization

Retrofitting is a cost-effective alternative to purchasing new equipment. By upgrading only the necessary components, substantial improvements in performance can be achieved without incurring the high costs associated with new machinery. This strategic approach ensures that you maximize your investment while enhancing operational efficiency.

2) Minimized Downtime

One of the primary advantages of retrofitting is the reduction in downtime. Upgrading existing machinery typically requires less time compared to the installation of new equipment. This means minimal disruption to your operations, allowing your production to continue with fewer interruptions and maintaining business continuity.

3) Enhanced Efficiency

Integrating modern components and technologies into your existing machinery can significantly boost efficiency and productivity. This leads to faster processing times, reduced energy consumption, and lower operational costs. Enhanced efficiency directly translates into better performance and increased profitability.

4) Sustainability

Retrofitting promotes sustainable practices by extending the life of your existing equipment. This reduces industrial waste and aligns with global efforts to minimize environmental impact. By opting for retrofitting, you contribute to sustainability while optimizing your resources.

5) Improved Safety

Upgrading old equipment with new safety features protects your workforce and reduces the risk of accidents. Enhanced safety protocols also ensure compliance with the latest industry standards and regulations, fostering a safer working environment and reducing legal liabilities.

Conclusion: Future-Proof Your Operations

Retrofitting is not just a cost-saving measure; it’s a strategic investment in the future of your operations. By keeping your machinery up-to-date, you ensure sustained efficiency, reduced downtime, and enhanced productivity. Begin your journey towards optimized efficiency and productivity today!

At S A Automation Pvt Ltd, we specialize in identifying the optimal retrofitting solutions tailored to your specific needs. Our expertise ensures that your equipment remains competitive and efficient in an ever-changing industry landscape.

For more information or to schedule a consultation, please contact us or leave your questions in the comments below.

web: www.saautomation.com

mail: sales@saautomation.com

Contact: 9978923176

Comments

Post a Comment